產(chǎn)品分類

產(chǎn)品詳情

Stainless steel sanitary grade high speed emulsification shear dispersing emulsifier

掃描二維碼

分享到:

上一個:Stainless steel sanitary grade high speed gouache mixer

下一個:Sanitary stainless steel pipeline high shear dispersing emulsifier mixing equipment

產(chǎn)品詳情

working principle

A high-shear dispersing emulsifier is an efficient, fast, and uniform distribution of one or more phases into another continuous phase. In general, the phases are mutually insoluble. Due to the high tangential speed and high-frequency mechanical effects brought by the high-speed rotation of the rotor, the materials are subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer library rubbing, The combined effects of impact tearing and turbulence make the immiscible solid phase, liquid phase, and gas phase instantly and uniformly disperse and emulsify under the combined action of corresponding mature processes and suitable additives. Stable high-quality products.

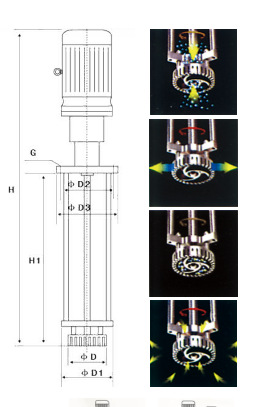

Shearing process

Under the action of the centrifugal force generated by the high-speed rotating rotor, the material in the picture is sucked into the working chamber from the axial direction at the same time from the upper and lower feeding areas of the working head. Strong centrifugal force throws the material from the radial direction into the narrow and tight gap between the stator and the rotor. At the same time, it is subjected to centrifugal extrusion, impact and other forces to make the material preliminary dispersed and emulsified. A linear speed of at least 15 m / s is generated at the outer end of the rotor that rotates at high speed, and the maximum speed can reach 40 m / s, and strong mechanical and hydraulic shear, liquid friction, and impact tearing are formed. The material can be fully divided, emulsified, homogenized, broken, and shot through the stator slot at the same time. The material is continuously ejected from the radial direction at high speed, and the flow direction is changed by the resistance of the material itself and the container wall. At the same time, under the action of the upper and lower axial suction forces generated in the rotor area, two strong upper and lower strands Flip turbulence. After several cycles of materials, the process of dispersion, emulsification and homogenization is finally completed