Product Categories

Product Detail

Share to:

Product Detail

Operation Principle

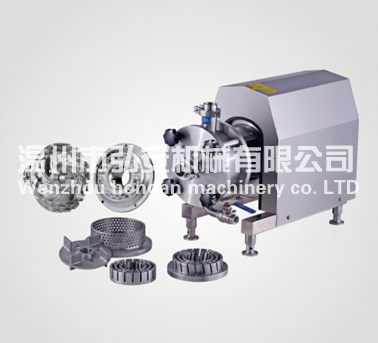

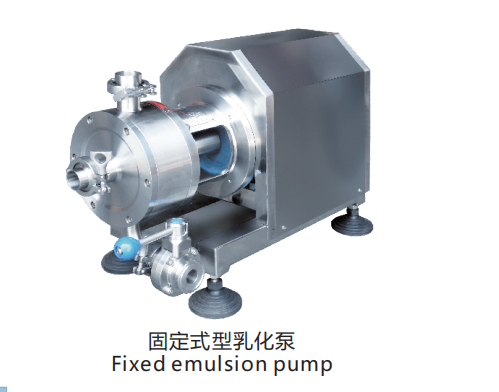

Pipeline high shear emulsifier is a high performance equipment used for continuous production or circulated treatment of fine material. In the small chamber, there are 1-3 sets of paired and clutched stators and rotor. Driven by motor, the rotor revolve quickly and produces a strong axial suctionforce which intakes the material to the chamber. The machine disperses, shears and emulsifiesthe material in shortest time, and the diameter range of the particles gets smaller so that fine and stable prcnjucts are produced.

Advantages Of Pipeline High Shear Emulsifier

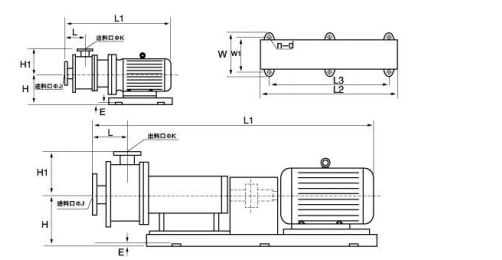

7.Daliver in short distance with low lift

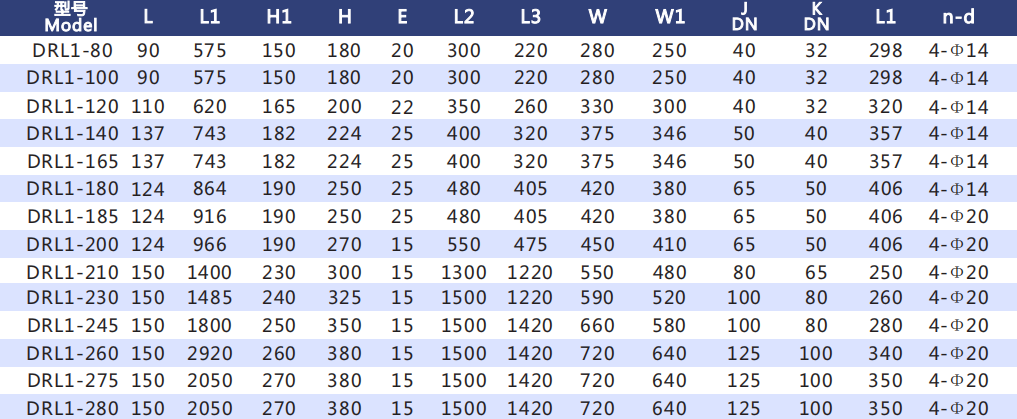

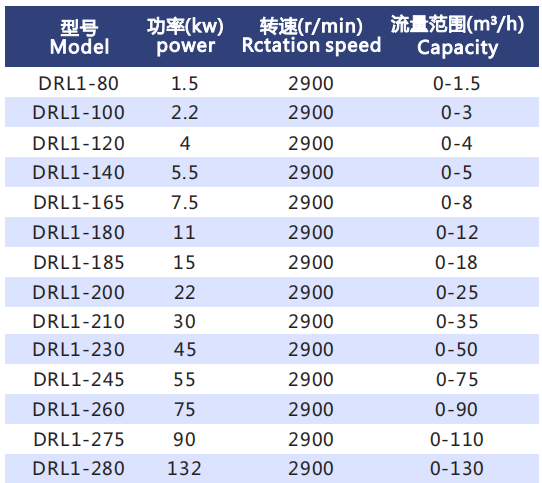

Note : the flow in the table refers to the data tested taking water as the medium, outlet pressure of the listed type≤0.2Mpa If circulated procedure is adopted, Intermittent high shear emulsifier is recommended. If there is high temperature, high pressure, flammable, explosive or corrosive condition, correct data should be provided by customers in order to customize the right producttype. For mediums that flow slowly, pumps of matched flow rate should be equipped in the inlet the pressure of pump≤0.2Mpa. The data in the table is subject to change without notice. See the actual products for theright data.