產(chǎn)品分類

產(chǎn)品詳情

分享到:

上一個(gè):Stainless steel vertical batching tank

下一個(gè):Stainless steel reactor

產(chǎn)品詳情

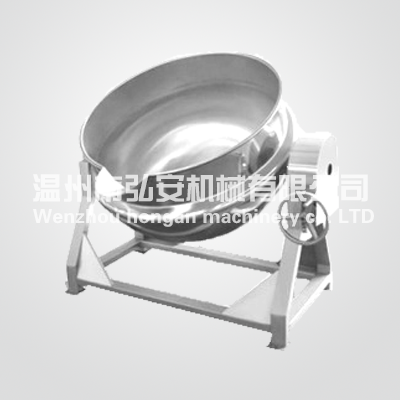

Sandwich pots are also known as steam pots, cooking pots, and sandwich steam pots. It usually consists of a pot and feet. The pot body is a double-layer structure composed of an inner and outer spherical pot body, and the middle interlayer is heated by steam. There are fixed, tilting, stirring and other styles. The sandwich pot has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid materials, easy control of heating temperature, beautiful appearance, easy installation, convenient operation, safety and reliability. Sandwich pots are widely used in the processing of various foods, and can also be used in large restaurants or canteens to cook soups, cook vegetables, stew meat, porridge, etc. It is a good equipment for food processing to improve quality, shorten time, and improve working conditions.

Introduction to basic performance:

1. Volume: 50L, 100L, 200L, 300L, 400L, 500L, 600L, 800L, 1000L.

2. Structural form: It can be divided into tilting type and vertical type, with or without stirring according to the process requirements.

3. Pot body material: ① inner pot body stainless steel (SUS304), jacket, bracket carbon steel (Q235-B) coated with anti-rust paint; ② inside and outside all stainless steel.

4. Pot body with stirring device: central stirring at the top, the output shaft of the reducer and the stirring paddle shaft are connected by a sleeve, which is convenient for disassembly and cleaning.

5, stirring speed: 36r / min (can choose a certain speed according to customer requirements);

Type of stirring paddle: ordinary stirring (anchor type) and scraping bottom stirring.

6. Feet form: ① vertical pot body: triangular pyramid, round tube type; ② tiltable pot body: trough support type.

7. Equipment configuration: dial pointer thermometer, steam inlet, discharge port, etc. (vertical structure).

8. The tilting sandwich pot body can tilt up to 90 °, and the tilting method is manual turning.

Note: Jacket working pressure, motor power, heating power, stirring slurry structure, etc. can be customized according to customer's special requirements.