Product Categories

Product Detail

Share to:

Prev:Mobile cart type sanitary grade stainless steel colloid mill

Next:no more

Product Detail

working principle:

Colloid mill works by shearing, grinding and high-speed stirring. Grinding relies on the relative movement of two toothed surfaces, one of which rotates at high speed and the other is stationary, so that the material passing between the toothed surfaces is subject to

Great shearing force and frictional force, meanwhile, it can effectively disperse, emulsify, crush and homogenize materials under the action of complex forces such as high frequency vibration and high speed vortex. JMF / JML series colloid mill is a new type of wet ultrafine particle processing equipment, suitable for all types of semi-fluid, fluid, emulsion homogenization, emulsification, mixing, crushing, etc.

Application:

Food industry: aloe vera, broken pollen, pineapple, sesame, fruit tea, ice cream, moon cake filling, cream, jam, fruit juice, soy, bean paste, bean paste, peanut milk, protein milk, soy milk, dairy products, wheat milk horizontal, flavor , Various beverages, emulsified chicken bone mud, emulsified pig skin and other animal skins.

Chemical industry: paints, pigments, dyes, coatings, lubricants, sea grease, diesel oil, petroleum catalysts, emulsifiers, adhesives, detergents, plastics, fiberglass, leather, etc.

Daily Chemicals: Toothpaste, detergent, shampoo, shoe polish, cosmetics, bath essence, soap, balm, etc.

Medicine and chemical industry: syrup, nutrient solution, proprietary Chinese medicine, paste medicine,

Biological products, cod liver oil, pollen, bee milk, vaccines, various ointments, various oral solutions, injections, intravenous drips, pancreatin preparations, emulsions, herbicides, etc.).

Other chemicals: plastic industry, textile industry, paper industry, biochemical industry, environmental protection and energy saving, coal flotation agent, nano-materials, universities, research institutes, etc

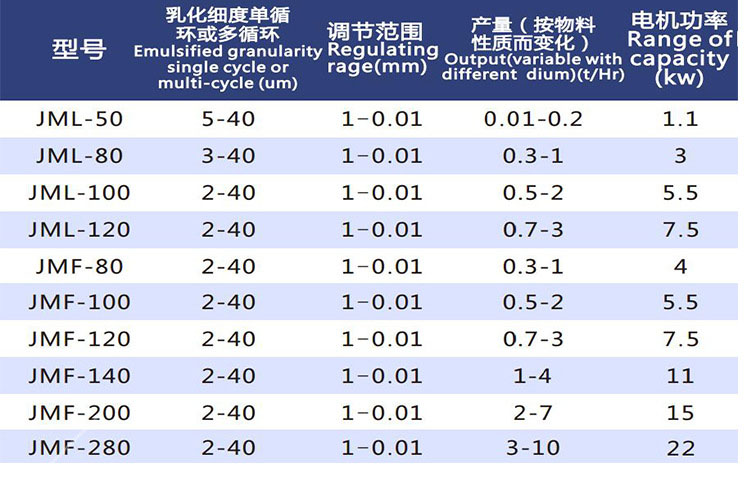

Main Parameter: