Product Categories

Product Detail

Share to:

Product Detail

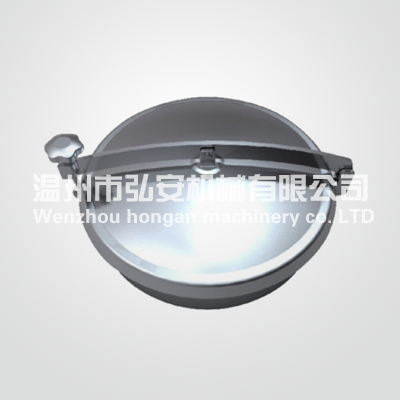

Manhole

Manhole (boiler, sewer for people to enter and overhaul) manhole, manhole Weak current wells for televisions, internal passages for maintenance of large bridges, etc.

Introduction

Manholes are safety emergency ventilation devices installed on the top of storage tanks. They are usually used in conjunction with fire extinguishers and mechanical breathing valves. They can avoid accidents that cause damage to the storage tank when accidental overpressure or vacuum occurs in the tank. It has the function of safety and fire resistance, is a safety device to protect the storage tank, and is particularly suitable for vaulted atmospheric pressure tanks whose storage materials are capped with nitrogen. It has the advantages of constant pressure discharge, constant pressure suction, flexible opening and closing, safe fire resistance, compact structure, good sealing performance, safety and reliability.

Manholes are divided into emergency pressure relief manholes, explosion-proof fire-resistant breathing manholes, tank top manholes, tank wall manholes, and core manholes.

Manholes are usually made of 304,316L stainless steel plate or carbon steel.

structure

Manholes already have molded products, usually 600mm in diameter. The center of the manhole is 750mm from the floor. It is convenient for workers to enter and exit the oil tank or ventilate during installation, cleaning and maintenance.

The manhole of the non-metallic oil tank is set on the tank top, and the manhole of the metal oil tank is set on the bottom plate of the tank wall. Most of them are circular holes with a diameter of 600mm, and the center is 750mm away from the bottom plate. It is used for tank cleaning or maintenance personnel to enter and exit the tank, which is also called door. Manholes are used for lighting and ventilation during maintenance and cleaning. When the capacity of the vertical oil tank is below 5000m3, 1 ~ 2 manholes are provided, and above 5000m3, 2 manholes are provided. The installation of manholes should be no more than 90 ° away from the oil inlet and outlet pipelines. When only one manhole is provided, it should be placed opposite to the transparent hole on the top of the tank; when two manholes are provided, one of them is located opposite to the light transmission hole, and the other should be at least 90 meters away from the first manhole °.

The manhole should be located near the right side of the oil inlet and outlet pipes, and try to keep the manhole directly against the closed door of the tank room, so that personnel can enter and exit, repair the oil tank and take over the ventilation.

Since the manhole is installed on the bottom body ring of the oil tank, leakage prevention is particularly important. It is required that the joint surface of the two flanges must ensure its straightness and no flutter. The reinforcing plate and flange should be cut on the whole steel plate without splicing as much as possible. Flange and cover plate are machined with sealing rings. Pay special attention to protection during construction. 3mm thick asbestos rubber gasket is used for sealing. When installing the manhole cover to tighten the bolts, apply force evenly in diagonals to prevent the hole cover from deforming.